Wood Floor Sanding Service in Portsmouth

At Floor Restoration Team, we specialize in professional wood floor sanding services for homes and businesses in Portsmouth and the surrounding areas. With years of experience, we are passionate about bringing out the natural beauty in your wood floors, ensuring they look as stunning as the day they were installed. From minor touch-ups to full restorations, we’re your go-to experts for all things floor sanding.

What Comes with Our Wood Floor Sanding Service?

When you choose our wood floor sanding service, you’re not just hiring a contractor—you’re investing in quality craftsmanship and a comprehensive service that includes:

- Free Initial Consultation & Quote: We begin with a detailed consultation, assessing the condition of your wooden floors and understanding your needs. We’ll provide a no-obligation quote, ensuring complete transparency from the start.

- Advanced Dust-Free Technology: Our state-of-the-art sanding equipment ensures minimal dust disruption, keeping your home or business clean while protecting the air quality for you and your family or employees.

- Multi-Stage Sanding Process: We use a multi-stage sanding process to remove old finishes, scratches, and surface damage. We take great care at every stage, from rough sanding to fine polishing, ensuring your wood floors are completely smooth and ready for finishing.

- Custom Finish Options: After sanding, we offer a wide range of finishing options to suit your style. Choose from high-gloss varnishes, matte oils, natural wood stains, and more, all designed to protect your floor and enhance its natural beauty.

- Repairs and Stain Removal: If your floor has deep scratches, stains, or even damaged boards, we can repair and replace sections as needed, ensuring a flawless finish.

- Aftercare Advice: We provide expert advice on how to maintain your freshly sanded and finished wood floors, including cleaning tips and guidance on how to keep your floors looking beautiful for years to come.

How Our Wood Floor Sanding Service in Portsmouth Solves Your Problems

We understand that dealing with scratched, dull, or damaged wood floors can be frustrating. You might be worried about the high cost of floor replacement or the hassle of tackling the project on your own. That’s where we come in. Our wood floor sanding service is the perfect solution for:

- Restoring worn floors: If your floors have seen better days, sanding will strip away old varnishes, scratches, and stains, revealing the beautiful natural wood underneath.

- Avoiding costly replacements: Instead of installing new floors, sanding is a cost-effective way to breathe new life into your existing flooring.

- Improving your home’s aesthetic: Beautifully restored wooden floors can transform the look of any room, adding warmth, character, and elegance.

- Increasing property value: Well-maintained wood floors are a desirable feature for potential buyers or tenants, making our service a smart investment for homeowners and landlords.

By choosing Floor Restoration Team, you’re not just fixing your floors; you’re improving the overall look and feel of your space, saving time and money, and enjoying the lasting benefits of expert craftsmanship.

Who Will Benefit the Most from Our Service?

Our wood floor sanding service is designed for a wide range of customers:

- Homeowners: If your wood floors are scratched, faded, or dull, we can restore them to their former glory, creating a cozy and stylish home environment.

- Landlords and Property Managers: Our fast, efficient service ensures your rental properties remain in top condition, helping you attract higher-paying tenants with freshly polished floors.

- Businesses: From restaurants and cafes to offices and retail spaces, we help business owners maintain a professional and inviting atmosphere with beautifully restored wood floors.

- Builders and Renovators: If you’re renovating a property, our wood floor sanding service is the perfect finishing touch, bringing a timeless, polished look to any space.

Ongoing Benefits of Our Wood Floor Sanding Service

After the job is complete, you’ll continue to enjoy several benefits from our expert wood floor sanding:

- Longer Floor Lifespan: Properly sanded and finished floors are more durable and resistant to everyday wear and tear, ensuring they last for decades.

- Easier Maintenance: Freshly sanded and sealed floors are easier to clean, requiring less frequent polishing and reducing the build-up of dirt and grime.

- Enhanced Indoor Air Quality: The removal of old finishes and scratches can eliminate dust, allergens, and bacteria trapped in the wood, contributing to a healthier indoor environment.

- A More Comfortable Living Space: Smooth, even floors improve the overall comfort of your home or business, creating a more enjoyable space for family, guests, or customers.

What Types of Wood Floors We Work With

We have extensive experience working with a variety of wood floor types, ensuring that each project is treated with the care and attention it deserves. No matter the style, pattern, or age of your wood floors, our team has the skills and equipment to handle them all. Here are some of the most common types of wood floors we work with:

- Parquet Flooring: Known for its intricate geometric patterns, parquet flooring requires delicate handling. Our sanding and restoration process brings out the beauty of each individual piece, ensuring the floor’s unique design is preserved.

- Hardwood Flooring: Whether you have oak, maple, cherry, or another type of hardwood, we specialize in sanding and refinishing to restore the natural grain and shine of the wood.

- Engineered Wood Flooring: Engineered wood can be sanded carefully to remove surface damage and restore the finish without harming the structural layers underneath.

- Pine Flooring: Pine is a softer wood that needs a gentle touch during the sanding process. We have experience working with this classic and beautiful wood to ensure a smooth, even finish.

- Bamboo Flooring: Although technically a grass, bamboo is treated much like wood and can be sanded and refinished to bring out its natural strength and beauty.

- Reclaimed Wood Flooring: If your home or business features reclaimed wood, we can carefully sand and restore these floors to maintain their rustic charm while enhancing their durability.

- Solid Wood Plank Flooring: Whether wide or narrow, solid wood plank flooring can be revitalized through our expert sanding services, revealing the natural richness of the wood.

Whatever type of wood flooring you have, оur team is able to restore it to its original beauty. Our expertise covers a wide range of wood types, allowing us to customize our approach to meet the specific needs of your flooring.

Commercial Wood Floor Sanding in Portsmouth

In addition to residential projects, We also specializes in commercial wood floor sanding for businesses throughout Portsmouth. We understand that the appearance of your business is critical to creating a professional and welcoming environment for customers, clients, and employees. High-traffic areas in commercial spaces often take a beating, leaving your wood floors dull, scratched, and worn out. Our expert team is equipped to handle commercial wood floor sanding for:

- Offices

- Retail stores

- Restaurants and cafes

- Hotels

- Schools and universities

- Sports halls and gyms

Why Choose Commercial Wood Floor Sanding?

- Create a lasting first impression: Beautiful, well-maintained floors give your business a polished, professional look that can enhance customer experience and reflect positively on your brand.

- Extend the life of your flooring: Regular sanding and refinishing can help extend the lifespan of your floors, saving you money on costly replacements and minimizing downtime.

- Improve safety: Worn and uneven floors can become a safety hazard in high-traffic areas. Sanding restores the surface, creating a smooth and even finish that is safer for both employees and customers.

Tailored Solutions for Your Business

We offer flexible scheduling and customized services to meet the specific needs of your business. Whether you need sanding during off-hours to avoid disruption or require a fast turnaround for a grand opening or event. Floor Restoration Team can work around your schedule to minimize any inconvenience. With our advanced dust-free technology and skilled team, we ensure minimal disruption to your business operations, leaving you with beautifully restored floors that enhance the overall atmosphere of your commercial space.

Let us help you maintain the beauty and integrity of your wood floors, giving your business the professional look it deserves. Contact us today to learn more about our commercial wood floor sanding services in Portsmouth.

Our Wood Floor Sanding in Portsmouth!

We know you have choices when it comes to wood floor sanding services, but here’s why Floor Restoration Team stands out from the competition:

- Local Portsmouth Experts: As a locally owned and operated business, we have extensive experience working with a variety of wood floors in Portsmouth homes and businesses. We understand the unique challenges of the area’s older properties and modern spaces alike.

- Highly Trained Specialists: Our team consists of skilled professionals who have honed their craft through years of experience. We stay up-to-date on the latest techniques and technology, ensuring you receive the highest quality service.

- Customer-Focused Approach: We pride ourselves on delivering excellent customer service. From start to finish, we communicate clearly, respect your time and property, and always aim to exceed your expectations.

- Competitive Pricing: We offer some of the most competitive rates for wood floor sanding in Portsmouth without compromising on the quality of our work. We also provide clear, upfront pricing, so there are no hidden costs or surprises.

- Sustainability: We care about the environment and use eco-friendly products wherever possible. Our dust-free sanding process minimizes waste and creates a cleaner, healthier environment for you and your family.

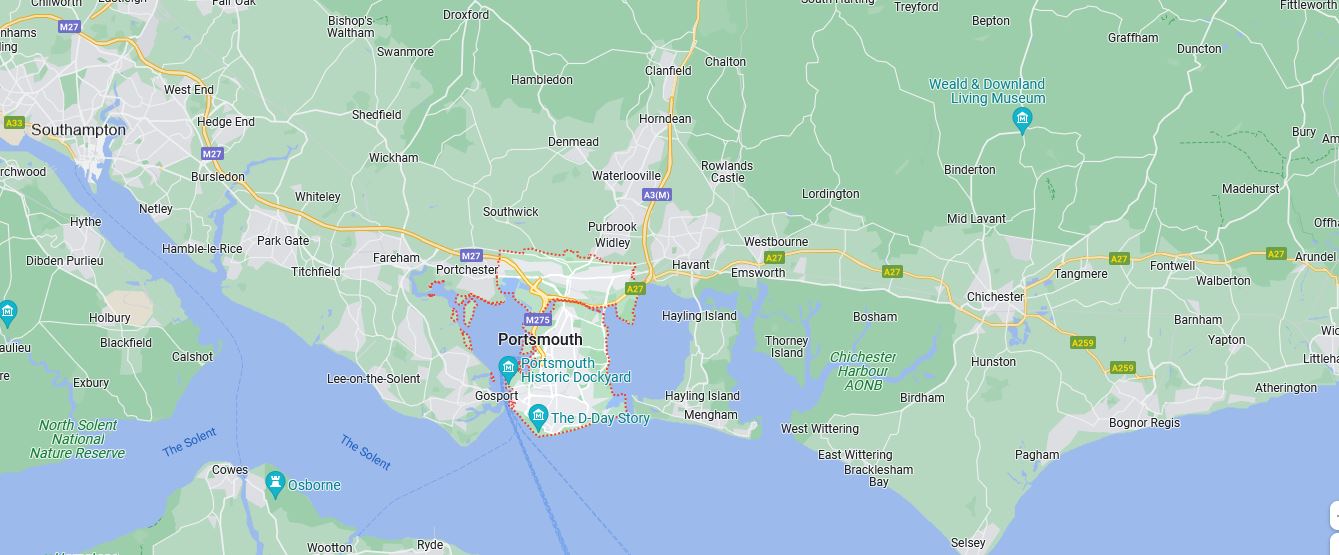

Areas We Cover in Portsmouth

We proudly provide our wood floor sanding services to Portsmouth and the surrounding areas. Whether you’re based in the heart of the city or in the nearby suburbs, we are ready to restore your wooden floors to their former beauty. Here are some of the areas we cover, along with their corresponding postcodes:

Portsmouth and Surrounding Areas:

- Portsmouth City Centre – PO1

- Southsea – PO4

- Eastney – PO4

- Fratton – PO1, PO2

- Copnor – PO3

- Milton – PO4

- North End – PO2

- Hilsea – PO3

- Old Portsmouth – PO1

- Cosham – PO6

- Drayton – PO6

- Farlington – PO6

Nearby Areas:

- Havant – PO9

- Waterlooville – PO7

- Fareham – PO14, PO15, PO16

- Gosport – PO12, PO13

- Portchester – PO16

- Emsworth – PO10

- Hayling Island – PO11

If you’re located in any of these areas and are in need of professional wood floor sanding, don’t hesitate to contact us. We’re committed to providing top-quality service to homes and businesses across Portsmouth and beyond.

Here is what is sanding floors all about:

What is wood floor sanding?

The essence of floor sanding work is removing the top layer with all the dirt, grime and small damages, so that a fresh layer of wood is revealed underneath. However, the whole process is a lot more and is usually done in several stages.

Wood Floor repairing

Before the actual sanding takes place, the floor needs to be inspected and any loose or damaged floorboards made good – re-fix loose boards with headless nails and replace broken ones. Depending on the particular situation we may use reclaimed timber that matches the colour of your floor in order to fix it.

Floor Gap filling

The next procedure although not a must, but most people opt to have this done, as it gives equal finish to the floor. The other benefits of the gap filling is that it insulates the floor and prevents dirt build-up between boards. The floor gaps appear either due to the age of the wood floor or based on the usage. However small gaps (up to 5mm) are usually filled with a mixture of resin and dust from the initial sanding. Although the most cost-effective method, this is also the shortest to last, since, once the mixture dries, the resin shirks with time and either falls below the boards, or you vacuum it out. Depending on the floor gap our team may use proper silicone to too. Our wood floor sanders are trained to choose the most suitable method for filling and fixing the gaps.

The more expensive, but also the longer lasting method is to seal with timber fillets that are cut to size and glued into position. As fillets move with the boards during seasonal expansion of the wood, this repairing method can have your floor filling last for decades.

Wood floor sanding

This is the main procedure which done in couple stages – a coarse grade sand paper is used to strip away old sealant and paint, then a finer grade sanding papers, to give the floor a smooth and even finish and prepare the floor for sealing. We use professional floor sander machinery and equipment, thus the sanding is nearly dust-free. Which compared to the old belt driven sanders is a great plus for the homeowners.

Floor Staining

The following procedure is optional and its based entirely of you. What is floor staining? The floor staining can give your floor the desired looks – whether all-natural or a colour that matches your room’s décor. You can choose from large portfolio of colours for your floor. If you deside to skip the staining, then the floor will remain with the natural colour of the wood – which is great too! Please note that there is nothing to worry when choosing to go with staining, as the Stains are now produced environmental-friendly and completely safe for you, your family and pets.

Floor Sealing and Varnish

Whether you chose to stain the floor or not, it will require finishing with a protective sealant. This also comes in different choices – varnish or oil.

Varnish (laquer) is usually applied on heavily used floors, as it is a durable sealant. However, since modern varnish is made of polyurethane (which is, basically, liquid plastic). Based on the floor traffic the laquer may eventually crack or peel our team is doing their best to prevent that.

The floor oil is manufactured from natural materials. Unlike the varnish, which is applied ON the wood, oil penetrates into the timber and doesn’t crack/peel. It is easy to maintain and can be re-applied when needed, without having to sand the floor anew.

Note that wood sanding is also applicable for wooden counter tops.

Ready to Transform Your Wood Floors?

If you’re ready to bring your wooden floors back to life, contact us today. We offer a free, no-obligation consultation and quote for all wood floor sanding projects in Portsmouth. Whether you’re looking to refresh a single room or restore an entire property, we’ve got you covered.

Call us at 0203 670 5800 or contact us online to schedule your consultation and see how our professional wood floor sanding service can make a lasting difference in your home or business.

Frequently Asked Questions (FAQ) About Our Wood Floor Sanding Service

1. How long does the wood floor sanding process take?

The duration of the wood floor sanding process depends on the size and condition of the area being worked on. For a standard room, sanding typically takes 1-2 days, including sanding and finishing. Larger or heavily damaged floors may take longer, especially if additional repairs or custom finishing options are needed. We always provide an estimated timeframe during our initial consultation to ensure minimal disruption to your schedule.

2. Will there be a lot of dust during the sanding process?

No, our wood floor sanding process is virtually dust-free. We use the latest dust-free sanding technology, which captures dust as it’s created, ensuring your home or business remains clean. This means you won’t have to worry about excessive cleanup or dust spreading to other areas of your property, providing a hassle-free experience.

3. Can you sand engineered wood floors?

Yes, we can sand most engineered wood floors. However, engineered wood has a thinner top layer compared to solid wood, so it can only be sanded a limited number of times. During our consultation, we assess the thickness of the top layer to ensure it’s suitable for sanding, providing you with the best advice for restoring your floors.

These FAQs can help address common concerns and reassure potential customers about the quality and convenience of your service.